Understanding Different Types of Door Hinges

When it comes to door hardware, choosing the right hinges is essential for both functionality and aesthetic appeal. A well-selected hinge not only ensures smooth operation but also contributes to the overall look and durability of doors. An experienced Door Hinges Manufacturer will offer a variety of options to meet diverse needs. Let’s explore the different types of door hinges and their unique characteristics.

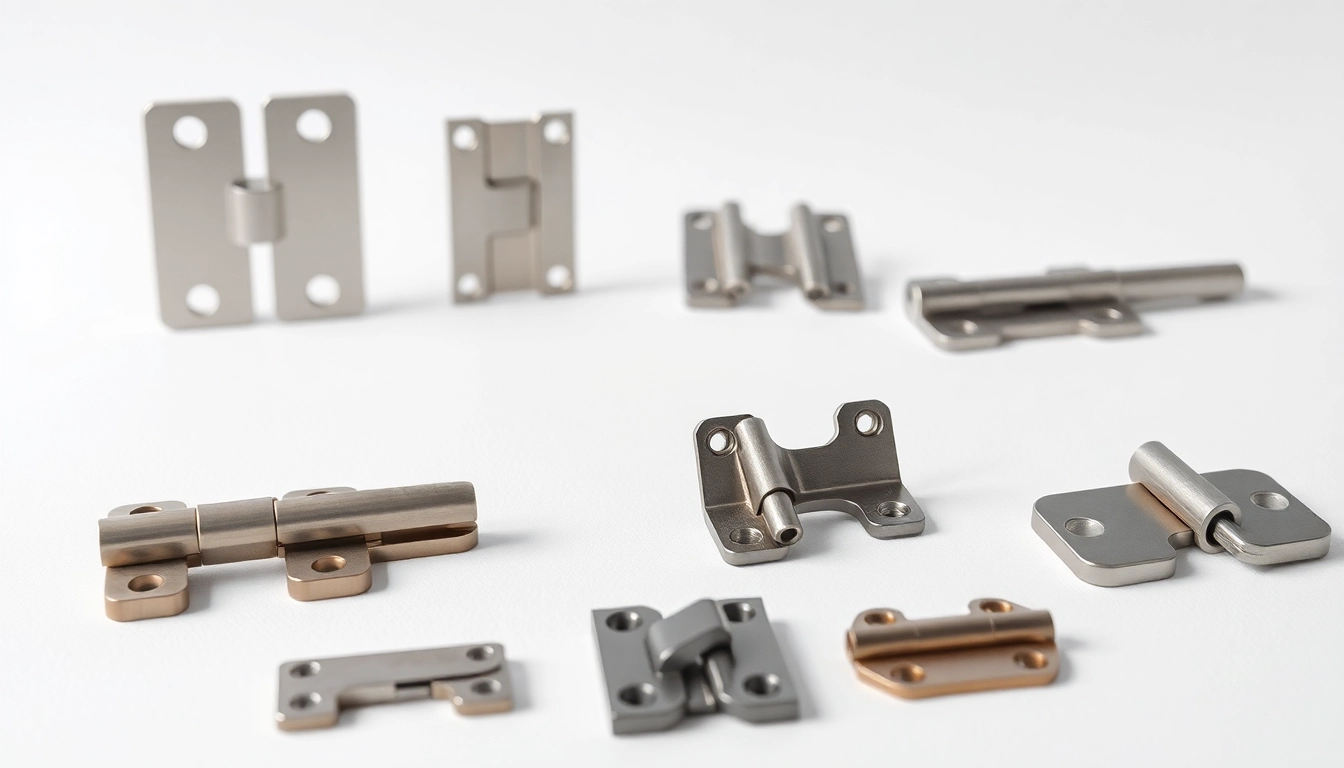

1.1 Butt Hinges: The Traditional Choice

Butt hinges are perhaps the most commonly recognized type of hinge in residential and commercial settings. Characterized by two plates, or leaves, which are attached to the door and the frame, they offer reliable support and security. These hinges are often made from brass or steel, making them durable enough for frequent use.

Butt hinges come in various sizes and weight capacities, which means they can be used for everything from interior doors to heavy-duty applications such as commercial entrances. Their straightforward design allows for easy installation, making them a go-to choice for many door hinge needs.

1.2 Concealed Hinges: Sleek and Subtle Design

Concealed hinges, also known as hidden hinges, offer a minimalist aesthetic as they remain hidden when the door is closed. This type of hinge is frequently used in modern cabinetry and interior doors where a clean look is desired. Concealed hinges come with adjustable features, allowing for precision in alignment and swing.

Due to their design, they are ideal for achieving a seamless appearance in contemporary architecture. However, their installation can be more complex and may require specialized tools, making them less favorable for DIY enthusiasts without proper skills.

1.3 Continuous Hinges: Reliability for Heavy Doors

Continuous hinges, also referred to as piano hinges, run the entire length of the door, providing uniform support. This makes them an excellent choice for heavy doors, such as those found in commercial or institutional settings. They distribute weight evenly across the door frame, reducing wear and tear at the pivot point.

Continuous hinges can be made from various materials, including stainless steel and aluminum, which enhances their durability and longevity. Their robust build is particularly beneficial for high-traffic areas where doors undergo constant use.

Key Materials Used in Door Hinge Manufacturing

The choice of material significantly impacts the functionality and durability of door hinges. Different materials bring unique characteristics and strengths to the application. Here’s a look at the most common materials used in door hinge manufacturing.

2.1 Steel Hinges: Strength and Durability

Steel is one of the most popular materials for door hinges due to its strength and cost-effectiveness. Steel hinges can handle considerable weight and are less prone to bending or breaking under pressure. They are suitable for both residential and commercial applications, making them a versatile choice.

For added rust resistance, steel hinges can be coated or galvanized. This enhancement makes them suitable for exterior applications, where exposure to the elements can cause corrosion over time.

2.2 Brass Hinges: Aesthetic Elegance

Brass hinges are often chosen for their aesthetic appeal and resistance to corrosion. Their golden hue adds a touch of elegance to both classic and modern interiors. Brass is a softer metal, which may make it more susceptible to developing scratches, but the charm it brings to furniture and door frames can be well-worth it.

Brass hinges are commonly used in interior settings where aesthetics play a critical role, such as on high-quality solid wood doors and cabinetry.

2.3 Stainless Steel: Corrosion Resistance

Stainless steel hinges are celebrated for their corrosion resistance and high durability. This makes them an optimal choice for areas prone to moisture and humidity, such as kitchens and bathrooms. Stainless steel hinges are often found in commercial settings where durability is paramount.

Moreover, they are easy to clean and maintain, contributing to a hygienic environment, especially in commercial kitchens where hygiene standards are critical.

The Importance of Choosing the Right Door Hinge

Selecting the appropriate door hinge is crucial not just for function, but also for the longevity and safety of the door itself. An ill-fitted hinge can lead to misalignment, which can compromise the door’s integrity and functionality.

3.1 Impact on Door Functionality

The functionality of a door hinges is closely related to its type, size, and material. An inappropriate choice can lead to issues such as sagging doors, difficulty in opening and closing, or potential damage to the frame or door itself. It is vital to choose a hinge that matches the weight and usage frequency of the door.

For example, heavy doors require robust hinges that can withstand more weight, while lighter doors can function well with standard hinges. The wrong selection could make the door prone to unexpected failures.

3.2 Aesthetic Considerations for Interiors

Aesthetics are often just as important as functionality. The right hinge color, finish, and design can enhance the overall look of a door and the space around it. For instance, a stylish brass hinge can complement vintage or rustic interiors, while a sleek stainless steel hinge can enhance contemporary designs.

Additionally, concealed hinges may be better suited for modern designs, as they provide a seamless look that doesn’t distract from the door’s overall appearance.

3.3 Compatibility with Door Types

Different door types require different hinge configurations. For instance, a hollow-core door will require lighter hinges compared to a solid-core or heavy door. A heavy door may need multiple hinges to distribute weight evenly and enhance stability.

Understanding door size and weight is fundamental when selecting hinges. Additionally, you’ll want to consider the door’s intended use—whether it’s for privacy, entrance, or commercial use—and the environment in which it will reside.

Top Manufacturers in the Door Hinge Industry

The door hinge market is filled with ironclad manufacturers that also prioritize innovation and sustainability. Here we delve into some of the leading players in the industry.

4.1 Recognized Leaders in Innovation

Manufacturers like Hager and Stanley have set the standard for high-quality door hinges. They innovate constantly to create products that not only enhance functionality but also integrate modern technologies and materials. Hager, for instance, has been a pioneer in creating customized hinges suited for a range of specialized applications.

These manufacturers invest in research and development, ensuring their hinges meet evolving market demands and technological advancements, which is a crucial consideration for those in need of high-performance door hardware.

4.2 Sustainable Manufacturing Practices

As sustainability becomes increasingly important in manufacturing, top-tier hinge manufacturers are adopting eco-friendly practices. Companies are prioritizing recycled materials and sustainable methods throughout production. Many utilize processes that minimize waste and energy consumption, leading to a smaller environmental footprint.

For example, the use of recycled metals in hinge manufacturing not only supports sustainability but also helps in reducing costs. Realizing the impact of production practices on the environment is essential for manufacturers committed to long-term viability.

4.3 Global Supply Chain Solutions

A successful door hinge manufacturer must also have a robust and flexible supply chain to deliver quality products consistently. Companies must manage logistics effectively to ensure timely delivery of products around the globe. Recognized suppliers often have partnerships that allow them to source materials quickly and efficiently, minimizing delays.

By adapting to changing materials costs and market conditions, leading manufacturers can offer competitive prices and maintain their commitment to quality.

Best Practices for Installing Door Hinges

Proper installation is crucial for the performance of door hinges. Here is a comprehensive guide to ensure a seamless installation process.

5.1 Tools and Materials Needed

Before beginning hinge installation, gather the necessary tools: a screwdriver, a drill, a level, a measuring tape, and screws that are compatible with your chosen hinges. Having a small chisel on hand can also be beneficial for adjusting door frames if necessary.

5.2 Step-by-Step Installation Guide

- Measure the Door and Frame: Start by measuring the height and width of the door, as well as the frame to ensure the hinges are appropriately placed.

- Mark Hinge Placement: Typically, hinges should be installed 7 inches from the top of the door and 11 inches from the bottom. The final hinge should be ideally placed in the middle, with spacing evenly distributed.

- Chisel Out Hinge Mortises: Use a chisel to cut mortises into the door and frame for a flush fit. Ensure that the hinge leaf lies flat and is seated properly.

- Attach the Hinges: Secure the hinges to the frame first, followed by the door. Tighten screws firmly, ensuring no wobbling.

- Align and Test: Hang the door and check for alignment. Adjust if necessary by removing a hinge and readjusting its placement.

5.3 Common Mistakes to Avoid

Several common errors can occur during hinge installation. One major mistake is failing to level the door properly before installation. A misaligned door will cause friction and uneven wear over time. Always check for level before securing screws.

Another pitfall is over-tightening screws, which can strip the holes and lead to hinge failure. Use sufficient pressure, but avoid excessive force. It is also wise to double-check that the right hinge type is chosen for the weight and style of the door to prevent a host of issues down the line.